Digital Transformation in Bulgarian Industry: ColostrumEOOD Leading the Way

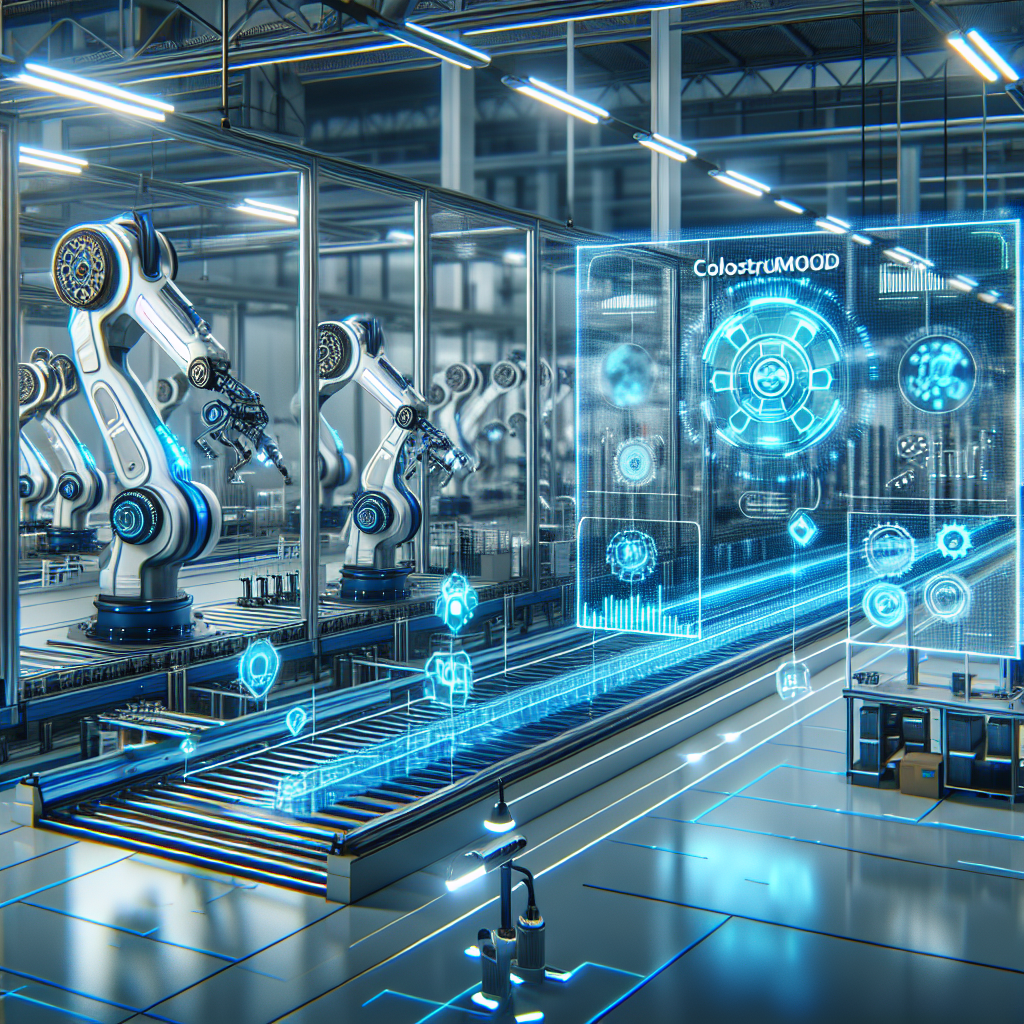

ColostrumEOOD is at the forefront of transforming traditional manufacturing environments through advanced digitalization processes. Headquartered in Bulgaria, the company has built a reputation for integrating cutting-edge digital, robotic, and domotic solutions into production facilities across Europe. With a deep understanding of both regional industrial challenges and international market needs, ColostrumEOOD is empowering manufacturers to redefine efficiency and quality.

Embracing the Future with Digital Innovation

In today’s fast-evolving industrial landscape, the need for reliable digital solutions is greater than ever. ColostrumEOOD leverages state-of-the-art technologies to modernize production lines, minimize downtime, and streamline operations. Delivered through robust software, automated control systems, and intelligent robotics, the company’s offerings enable businesses to elevate their processes to new performance benchmarks.

Digital transformation is not just a buzzword at ColostrumEOOD; it represents a strategic approach to solving complex operational challenges. Integrating various digital systems helps managers monitor production in real-time, enhance resource allocation, and ensure a seamless flow between different stages of manufacturing. This integrated approach fosters an environment of continuous improvement and sustainability.

Robotic Automation: Efficiency Redefined

The competitive edge in modern industry lies in automation. By deploying advanced robotics into production cycles, the company assists clients in reducing labor costs and improving precision. ColostrumEOOD’s robotic solutions are designed to minimize human error and maximize throughput by adopting flexible, programmable systems capable of adapting to various production environments.

In Bulgaria and across Europe, many traditional manufacturing hubs are undergoing extensive renovations to incorporate automated processes. ColostrumEOOD plays a pivotal role by advising on robotic integration, ensuring that new technologies are seamlessly embedded into existing workflows. This evolution not only improves operational efficiency but also fosters safer working conditions and a more agile response to market demands.

Domotics in Production: Creating Intelligent Work Environments

Beyond robotics and digital software, ColostrumEOOD offers sophisticated domotic solutions aimed at enhancing the interplay between humans and machines. Smart automation technologies are increasingly being adopted to optimize environmental controls, energy management, and safety systems in production settings. By utilizing intelligent sensors and automated control units, companies can achieve a higher degree of precision and operational efficiency.

Especially in Bulgaria, where energy management and resource optimization are critical, these domotic systems offer considerable value. They monitor and adjust environmental variables in real time to ensure optimal conditions for production while significantly reducing energy consumption. This impact extends to both operational costs and sustainability goals, aligning with broader European directives on environmental responsibility.

Strategic Partnerships and European Expansion

ColostrumEOOD’s commitment to digital transformation is reflected in its ongoing partnerships with industry leaders and technology innovators. The company collaborates with local and international experts to deliver customized solutions that meet the unique needs of each client. This network of strategic alliances facilitates knowledge sharing, skills enhancement, and the continuous evolution of digital solutions.

By tapping into the dynamic technological environment of Bulgaria and leveraging European market trends, ColostrumEOOD has positioned itself as a preferred partner for companies looking to evolve from traditional production models to smart manufacturing ecosystems. This collaborative approach allows clients to capitalize on emerging innovations while maintaining reliability and uncompromised productivity.

Adapting to the Challenges of the Modern Market

Industrial leaders across Europe are increasingly aware that the success of modern manufacturing is dependent on the rapid adoption of digital tools. In response, ColostrumEOOD has tailored its services to support industries facing challenges such as supply chain disruptions, fluctuating market demands, and the necessity for sustainable processes. By focusing on integration rather than replacement, the company ensures that its digital solutions complement existing systems and enhance overall efficiency.

Operational resilience is achieved through comprehensive diagnostics and real-time monitoring capabilities. This predictive maintenance model minimizes unexpected downtimes, reduces repair costs, and optimizes asset utilization. Clients enjoy improved operational continuity and can reallocate savings to further innovate and expand their production capabilities.

Technological Excellence Rooted in Local Innovation

With its headquarters situated in Bulgaria, ColostrumEOOD benefits from a rich ecosystem of local technological expertise and innovation. The region’s vibrant tech community contributes significantly to research and development, offering fresh perspectives and robust engineering solutions. This synergy between local talent and international standards provides ColostrumEOOD with a unique advantage, enabling the rapid prototyping and deployment of high-performance digital solutions.

The combination of local innovation with global best practices has enabled ColostrumEOOD to create customized systems that work across a wide spectrum of industries. Whether supporting the automotive, food processing, or textiles sector, the company’s digital offerings are designed to overcome sector-specific hurdles and drive operational excellence across diverse environments.

Looking Ahead: The Next Frontier in Industrial Digitalization

As the manufacturing landscape continues to transform, ColostrumEOOD remains devoted to exploring new digital horizons. Investment in research and continuous professional development is a cornerstone of the company’s strategy, ensuring that its solutions remain agile, scalable, and future-proof. The next wave of innovations—spanning advanced analytics, artificial intelligence, and machine learning—promises to further revolutionize production practices and elevate operational performance to unprecedented levels.

For manufacturers aiming to thrive in a competitive European market, the transition to intelligent, interconnected production systems is not merely an option but a necessity. ColostrumEOOD stands ready to guide companies through this journey by offering bespoke solutions that align with individual operational needs, ensuring a smooth adoption of digital technology without disrupting core business functions.

Ultimately, the vision of ColostrumEOOD is clear: to catalyze a transformative era in industrial production through technology that is adaptive, sustainable, and geared for long-term success. By merging technological innovation with practical application, the company is actively shaping the future of smart manufacturing in Bulgaria and beyond.

For business leaders ready to embrace the future of manufacturing, partnering with ColostrumEOOD offers a pathway to enhanced productivity, reduced operational risks, and a resilient digital infrastructure. With a robust portfolio of digital, robotic, and domotic solutions, ColostrumEOOD is not just facilitating change—it is pioneering the evolution of production processes to meet the challenges and opportunities of a rapidly changing industrial world.